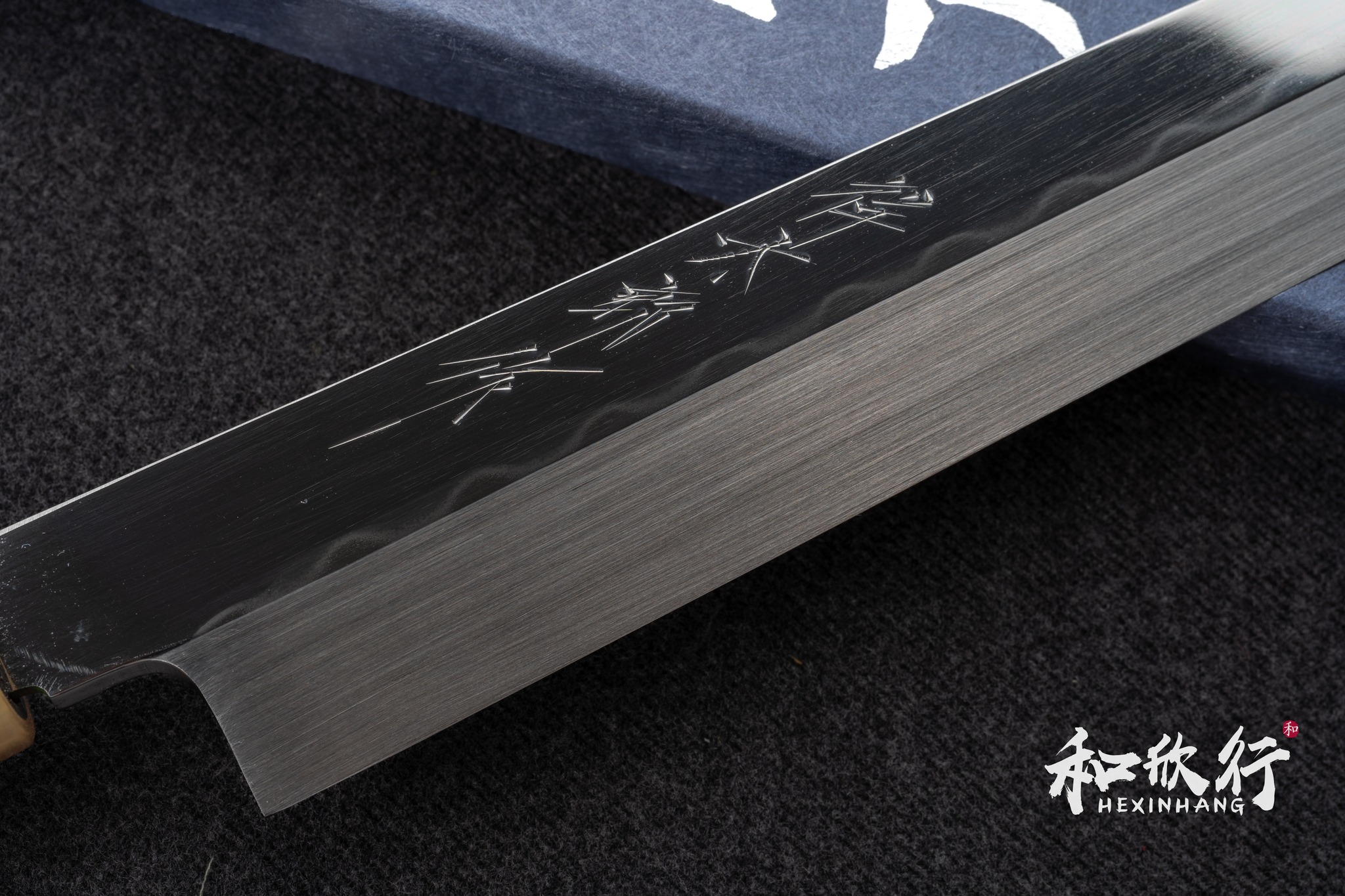

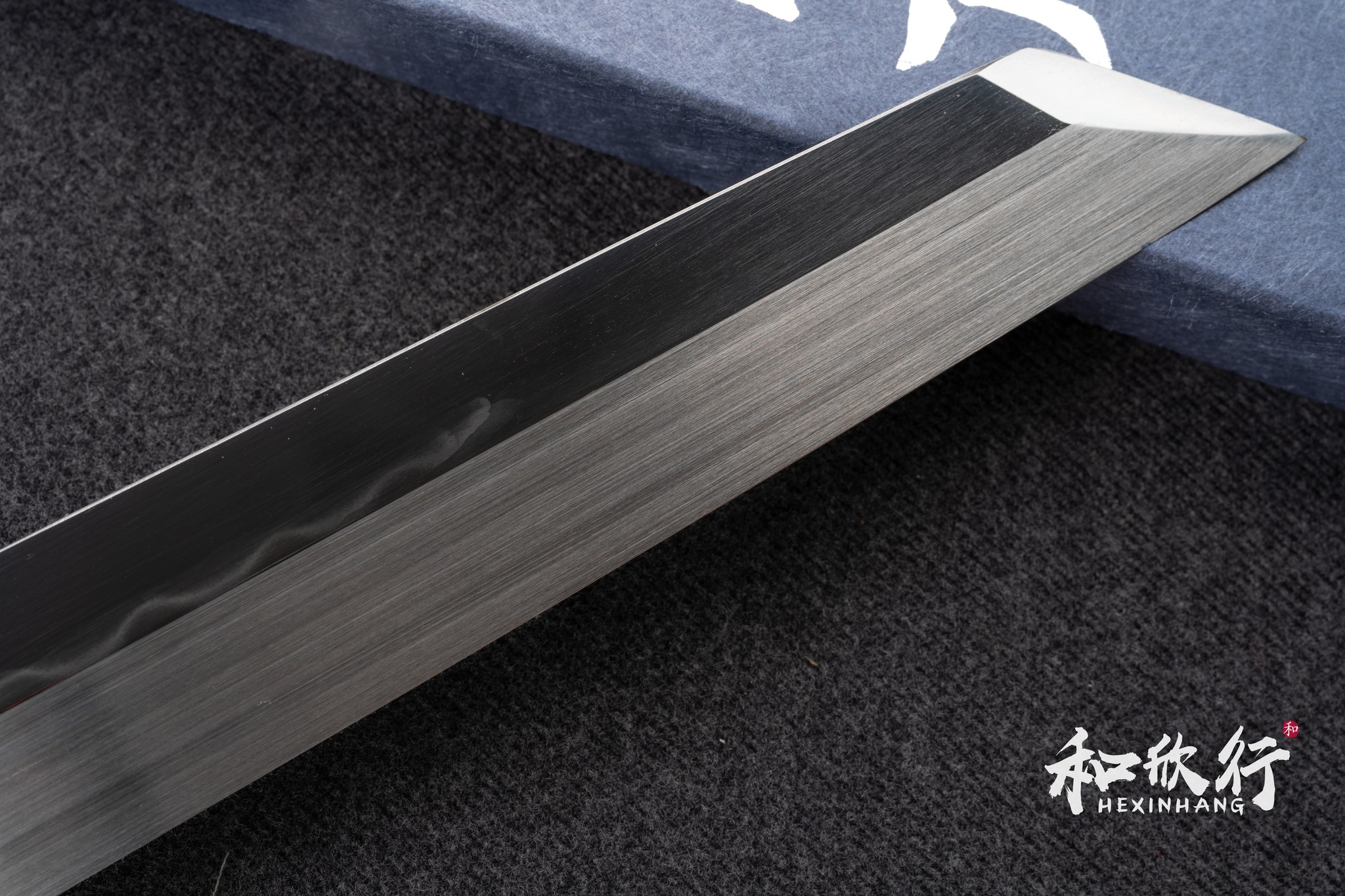

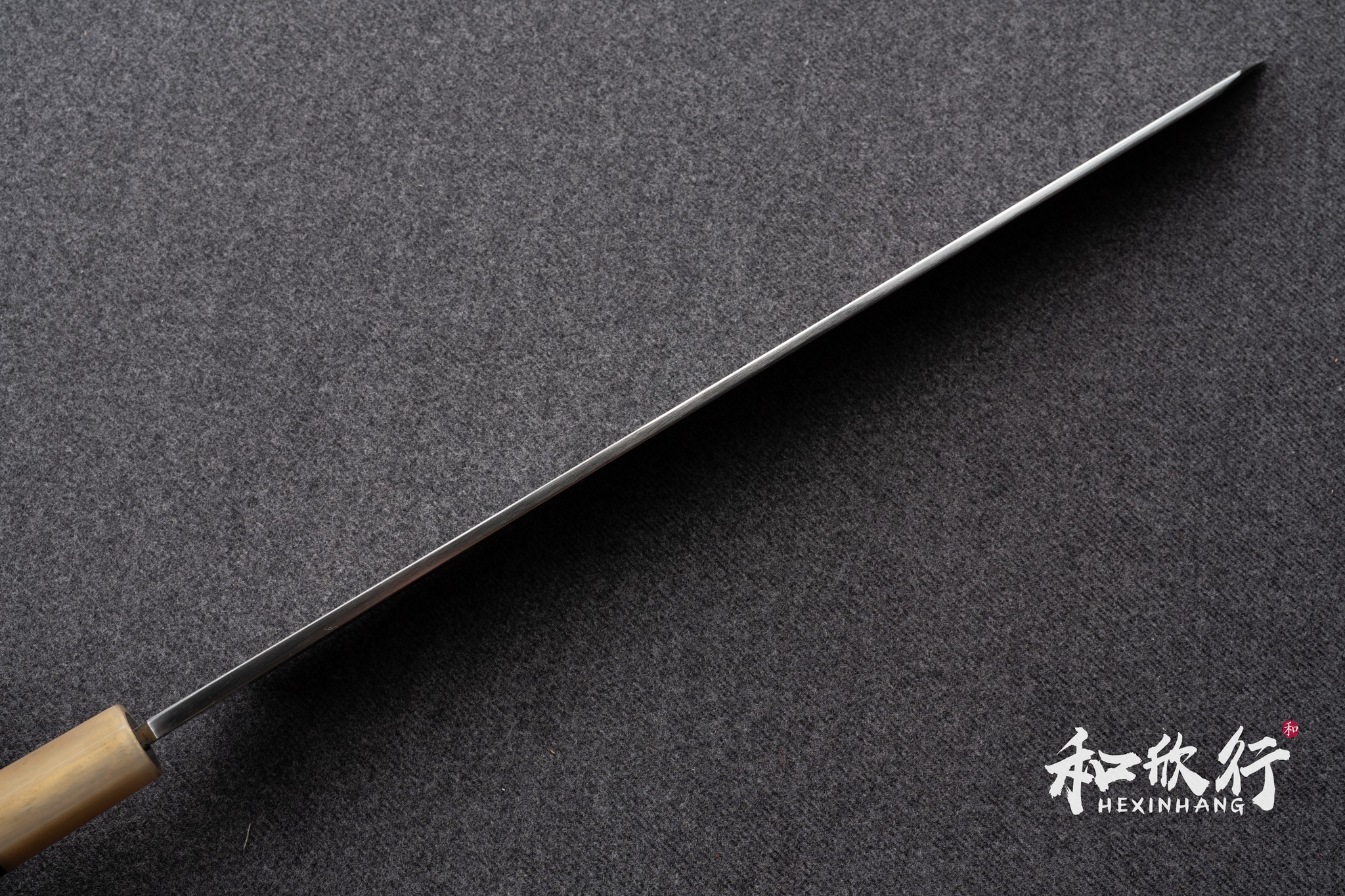

祥太郎 x 池田美和 作 青二鋼 本燒 劍型柳刃 300MM

請注意,此款皆為刀根落款~中子鋼印有池田美和以示證明。

關於池田鍛錬所:

池田美和先生 (Yoshikazu Ikeda) 於1967年開始鍛造刀具,作為其父親池田亀夫(Kameo Ikeda)的學徒,池田亀夫是池田鍛練所(Yoshikazu Tanrenjo)第二代鐵匠。哥哥池田辰男則接手了父親的作坊,成為第三代鐵匠。池田美和在1983年創立了自己的鐵打作坊“池田鍛錬所”。雖然一遍又一遍地做同樣的事情,但他並不會感到無聊。因此,幾十年來專注於掌握鍛造和工藝的技能,並獲得了許多獎項。堺北辰則是池田鍛練所工房所創作的一系列產品之一。

池田美和:

在1967年,我在父親作為鍛冶匠的指導下開始製作刀具,並於1983年獨立成立了池田鍛錬所。自那時起,我一直致力於堺打刃物的技術傳承,專注於製作和刀具。我主要製造專業用途的和式刀具,如水本燒和墨流し刀。在1988年,我獲得了國家的傳統工藝師認證,現在擔任著堺打刃物傳統工藝師協會的會長職務。

1988年 經濟產業大臣認定傳統工藝士

1999年 堺市商工功績賞

2004年 近畿經濟產業局長表彰

2014年 大阪府優勝技能者表彰(なにわの名工)

堺城內藏匠,磨刀先驅

野村祥太郎先生

■ 野村祥太郎(傳統工藝師)

從業年份:1962年

傳統工藝師認定年份:1988年

獲獎履歷:2009年 瑞寶單光章

野村先生師承於昭和時代的名匠伊野氏,深受其教導,對上等刃物有深厚的認知。不同於一般專注於品質和數量平衡的師傅(製作家庭用刀具的工匠),伊野氏告誡野村先生:“即便只有一把,也要打造出優質的作品。”野村先生獨立後一直秉持此教誨,不論面對何種訂單,皆以高水準的工藝(刃磨)回應。相較於其他工匠進行3個步驟的刀具處理,他執行4、5個步驟,不僅注重初見時的美感,更實踐了「研磨」的概念,使用過程中愈發體會到其優勢。

刃物磨刀已逾60年,年屆80的他居住在堺區甲斐町西,是一位備受推崇的名匠。他的作品榮獲瑞寶單光章等多項獎項,更入選為堺市的「堺百選」,贏得廣泛好評。

野村先生曾分享:“堺的和式廚刀擁有世界獨特的片刃形狀,表面使用鐵,背面使用鋼。由於合併兩種不同的金屬,一旦有任何一個步驟草率,就可能導致彎曲或扭曲。透過觀察金屬微妙的差異,磨刀達到鋒利的切割效果。正是堺的刃物支撐著和食文化中的『切味』。”

然而,刃物行業正面臨後繼者的嚴峻問題。他帶著寂寞的眼神表示:“當初進入這個領域時,刀具店有100家以上,但現在僅剩下約20家。儘管政府提供了支援,但找不到合適的接班人仍然是一大難題。許多得意客戶也向我們求情,希望我們培養後繼者,但實際上面臨重重難關。”

談及野村先生作為工匠的堅持,他微笑著說:“當達成一個目標時,就會有更高的目標,將好的刃物打磨成更好的刃物。要真誠地面對製作刀具的每一個步驟。儘管如此,每天的表現仍然會有所不同。但為了讓使用者感到高興,努力不息,刀具製作之道才是有趣的。”堺的名匠,不斷磨練自己的價值觀,追求著每日的滿足感。

(以上資料參考Google查詢之相關資料)

📌 訂單付款與配送方式說明

📢 親愛的顧客,您好:

🔹 因部分商品單價較高,無法使用「貨到付款」方式。

🔹 若商品尺寸超過超商配送的長度限制,也無法使用超商取貨服務。

📦 如您的訂單符合上述情況,我們將取消訂單,並主動通知您更改付款方式或配送方式。

⚠ 如造成不便,敬請見諒,感謝您的理解與支持!

📞 如有任何問題,歡迎聯繫我們。

🙏 謝謝!

Shotaro Nomura x Yoshikazu Ikeda Blue Steel Hon-yaki Yanagiba 300MM

Please note that this model bears the signature of the smith on the tang, and the blue steel is marked with Ikeda to indicate authenticity.

About Ikeda Tanrenjo:

Mr. Yoshikazu Ikeda began forging knives in 1967 as an apprentice to his father, Kameo Ikeda, who was the second-generation smith at Ikeda Tanrenjo. His brother, Tadao Ikeda, took over their father's workshop, becoming the third-generation smith. In 1983, Yoshikazu Ikeda established his own blacksmith workshop, Ikeda Tanrenjo. Although he repeatedly performs the same tasks, he never finds it boring. Therefore, he has focused on mastering forging and craft skills for decades, earning numerous awards. Sakai Hokushin is one of the series of products created by Ikeda Tanrenjo's workshop.

-

池田美和 Yoshikazu Ikeda :

In 1967, I began making knives under my father's guidance as a blacksmith and established Ikeda Tanrenjo independently in 1983. Since then, I have dedicated myself to preserving the technical heritage of Sakai's cutting tools, focusing on producing Japanese-style knives. I mainly manufacture traditional Japanese knives for professional use, such as Sujihiki and Gyuto. In 1988, I received national certification as a traditional craftsman and now serve as the president of the Sakai Traditional Craftsman Association.

Polisher: Traditional Craftsman Shotaro Nomura

A Pioneer of Knife Polishing from Sakai

Mr. Shōtarō Nomura

Mr. Nomura studied under the renowned craftsman Iino from the Shōwa era, deeply influenced by his teachings, and has a profound understanding of high-quality cutting tools. Unlike many artisans who focus on balancing quality and quantity (those who make household knives), Iino advised Mr. Nomura, “Even if it’s just one knife, it must be a quality piece.” Mr. Nomura has upheld this teaching since becoming independent, responding to every order with high standards of craftsmanship (sharpening). While other artisans handle knives in three steps, he executes four to five steps, not only paying attention to initial aesthetics but also embodying the concept of “polishing,” which he increasingly appreciates through the use of the tools.

With over 60 years of experience in knife polishing, at nearly 80 years old, he resides in the Sakai district of Kaicho-nishi and is a highly respected master. His works have won numerous awards, including the Order of the Rising Sun, and he has been selected as part of Sakai City's "Sakai 100 Selections," receiving widespread acclaim.

Mr. Nomura once shared, “Sakai's Japanese-style kitchen knives possess a unique single-edged shape in the world, with iron on the surface and steel on the back. Because two different metals are combined, if any step is rushed, it can lead to bending or warping. By observing the subtle differences in metals, sharpening achieves a keen cutting effect. It is precisely Sakai's blades that support the 'cutting taste' in Washoku culture.”

However, the knife industry is facing a severe succession issue. With a forlorn expression, he remarked, “When I first entered this field, there were over 100 knife shops, but now there are only about 20. Although the government provides support, finding suitable successors remains a significant challenge. Many loyal customers have urged us to cultivate successors, but we face numerous obstacles.”

Regarding Mr. Nomura's perseverance as a craftsman, he smiled and said, “When one goal is achieved, a higher goal emerges, refining good blades into even better ones. We must sincerely approach every step of knife-making. Nevertheless, each day's performance will still vary. However, to make users happy, the path of knife-making must be pursued with dedication, as that is what makes it interesting.” The master from Sakai continuously hones his values, pursuing daily satisfaction.

(The above information is referenced from related sources found through Google.)