藤次郎 Tojiro DP 三合鋼 牛刀、料理刀、主廚刀系列

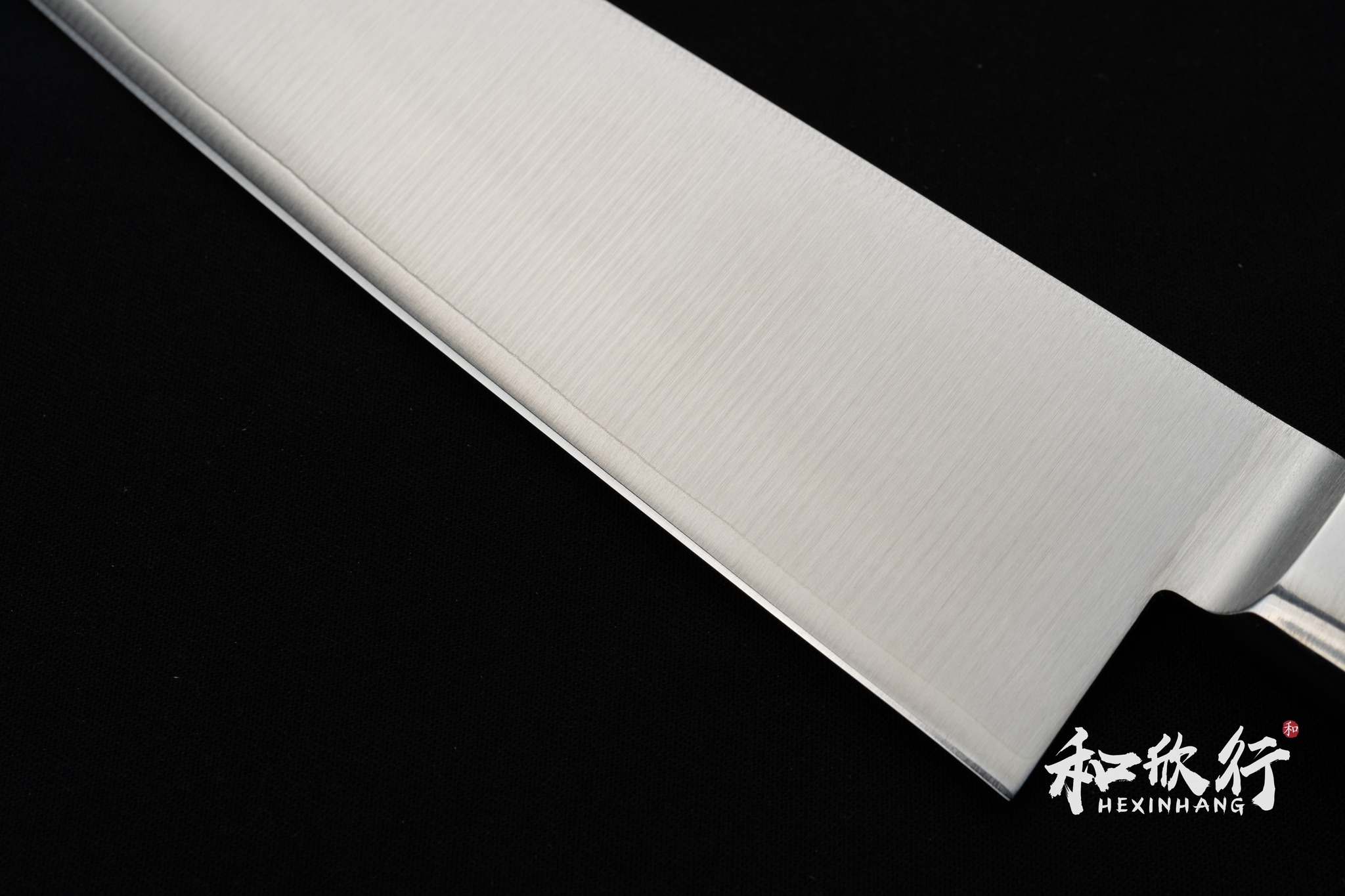

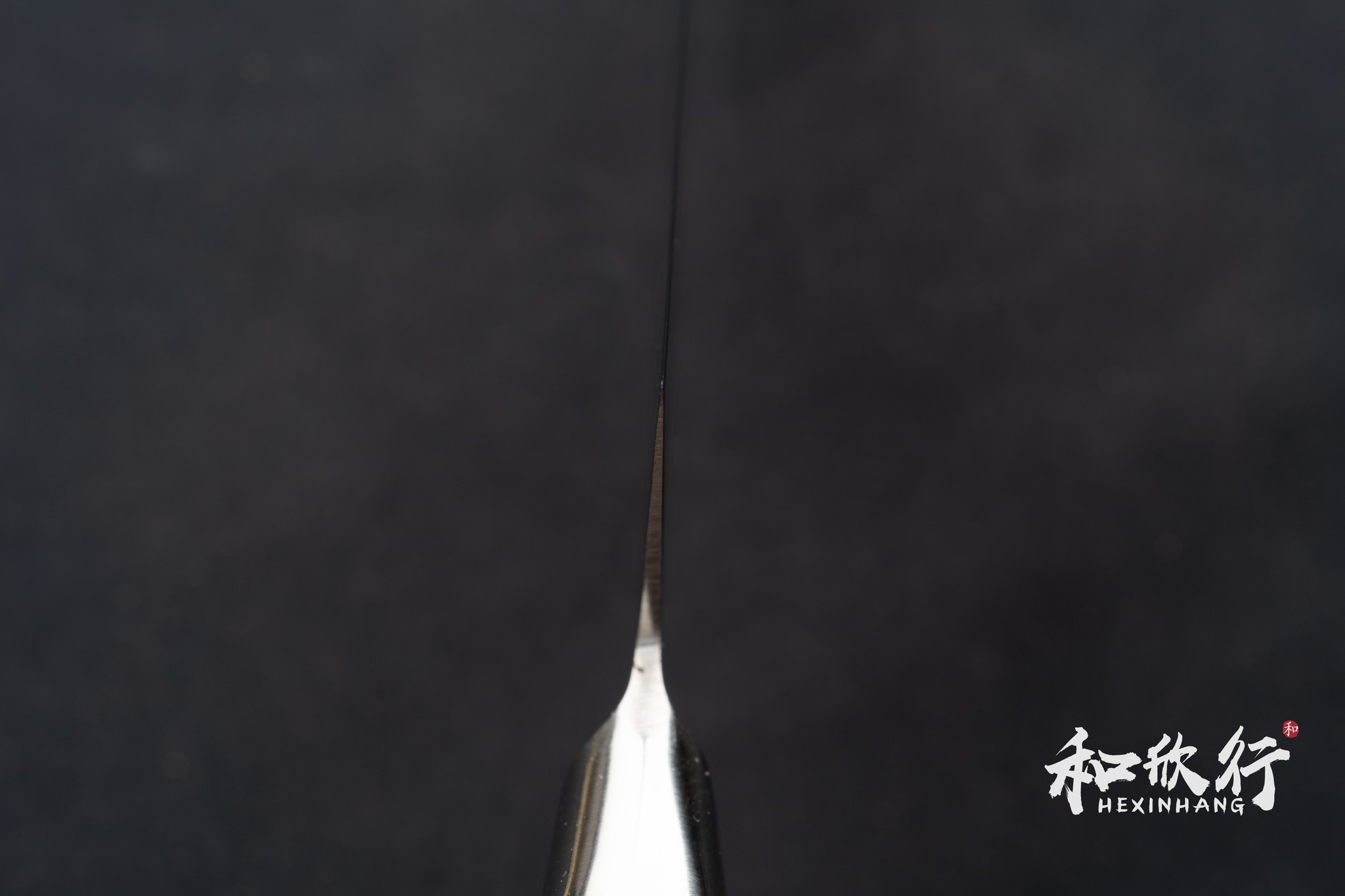

日本新刀出廠都可以直接用,其實根本不用再次開鋒。

再次開鋒只是把新刀一部分直接消耗掉~建議都是先用不利再磨!當然有需求也可以直接先幫你打薄。

型號:F-807

型號:F-808

型號:F-809

型號:F-810

型號:F-811

「一期一會」– 一生一次:

超越一把刀,TOJIRO在思考使用者的同時,持續製造刀具。人與人之間、刀具與人之間,都是「一生一次」。為了豐富這樣的相遇,我們製造刀具。

TOJIRO能為刀具做什麼:

TOJIRO刀具的歷史始於1955年推出的不鏽鋼水果刀。當時,人們認為不鏽鋼刀片的鋒利度不及碳鋼。因此,TOJIRO誠心追求「可切割的刀具」,實現不斷的改進與演變。如今,我們的企業訊息是「不僅僅是鋒利」。

我們希望不僅提供鋒利的刀具,還要讓使用者感受到刀具在手中舒適合適,成為他們的夥伴。我們持續努力精心製造刀具,確保每一把TOJIRO刀具都能給客戶帶來最大的滿足感。

傳承與創新:

傳承與創新在我們的製造過程中並存。

夾層鋼是我們生產中最常用的材料。它的鍛造方式與傳統日本刀「日本刀」的鍛造相同。

另一方面,我們的區域,位於新潟縣的燕市,是著名的金屬產品製造中心。這裡的金屬加工現代技術在幾十年中不斷改進,我們也在這方面表現優異。

在這裡,我們將傳統與現代技術相融合——使用沖壓機壓制夾層鋼板。換句話說,我們充分利用了夾層鋼的質量與現代機器的高生產效率。

雖然機器使得過程更為高效,但決定性因素仍然在於工匠的技能與直覺。由於刀具是人們直接使用的工具,我們重視生產者的技能,這是製造的基礎,並在所有過程中密切關注,直到每位TOJIRO的工匠完全滿意。我們的刀具,結合傳統技術與現代工業技術,在日本和全球都受到高度評價。我們,TOJIRO,將繼續在日本為數不多的全規模廚房刀具生產商中,追求傳承與技術創新之間的平衡。

工匠:

TOJIRO的工匠希望您能感受到使用工具的「喜悅」。他們每天磨練自己的技能,製造出值得的刀具。只要我們是工匠,提升技能的道路將永無止境。我們誠心每天為使用者製造刀具。由這種奉獻所誕生的產品,是製造者對客戶的訊息。

從燕三條到全世界:

我們在這片自古以來傳承了製造精神與技術的地區,持續製造最高品質的刀具。TOJIRO位於的燕市,是一個以金屬加工為主的工業集群地區,稱為「燕三條」。

自17世紀初開始製造和釘(Wakugi)以來,這裡生產了刀具、銼刀、管道、銅器、金屬雕刻、餐具等產品,並且出口量不斷增加。

TOJIRO已將來自日本代表性生產地區的產品傳遞到全世界,這裡的專業廠商在友好的競爭中共同發展技術與精神。

Tojiro DP Series - Three-Ply Steel Gyutō, Chef’s Knife

New Japanese knives come ready to use; there’s actually no need to sharpen them again.

Re-sharpening just consumes a portion of the new blade—it's recommended to use them first and sharpen as needed! Of course, if you need it, we can thin it out for you first.

Model: F-807

Model: F-808

Model: F-809

Model: F-810

Model: F-811

“ICHIGO ICHIE” – ONCE IN A LIFETIME:

Beyond a single knife, while thinking of its user, TOJIRO continues to manufacture knives. Person to person, person to knife, both are “once in a lifetime.” To enrich such encounters, we manufacture knives.

What TOJIRO can do for knives:

The history of TOJIRO knives started with the stainless steel fruit knife that was released in 1955. At that time, it was said that stainless steel blades were not sharp enough compared to carbon steel. Therefore, TOJIRO pursued in earnest “cuttable knives,” realizing continuous improvement and evolution. Today, our corporate message is “More than just sharpness.”

We wish to deliver not only sharpness but the feeling that a knife fits comfortably in your hands as you use it, becoming your partner. We are continuing our efforts to carefully manufacture knives so that a single TOJIRO knife can provide the greatest satisfaction to our customers.

Tradition and innovation:

Both tradition and innovation coexist in our manufacturing process.

Clad steel is the material that we use most in our production. It is forged in the same way as forging a traditional Japanese sword, “Katana,” from Tamahagane.

On the other hand, our area, Tsubame in Niigata Prefecture, is well-known as a center for manufacturing metal products. Modern technology of metal processing has therefore improved over the decades here, and we excel at it.

Here we merge tradition and modern technology—pressing out sheets of clad steel using stamping machines. In other words, we are taking advantage of the quality of clad steel and the high production efficiency of modern machines.

Although machines have allowed the process to become more efficient, the deciding factor lies, of course, in the skill and instinct of craftsmen. As knives are tools that people directly take into their hands to use, we value the skills of producers, which are the foundation of manufacturing, and keep a close eye on all processes until each craftsman at TOJIRO is completely satisfied. Our knives, produced by traditional techniques and modern industrial technology, are held in the highest regard not only in Japan but around the world. We, TOJIRO, will continue to strive for a balance between inherited tradition and technical innovation as one of the few full-scale production kitchen knife manufacturers in Japan.

Craftsman:

The craftsman at TOJIRO would like you to feel the “joy” of using a tool with attachment. They hone their skills to manufacture worthy knives daily. As long as we are craftsmen, the road to improving our skills will never end. We are earnest about making knives daily for users. A product born from such devotion is a message from the maker to the customer.

From Tsubame-Sanjo to the world:

We continue to manufacture the highest quality knives in this region where the spirit and techniques of manufacturing have been handed down since ancient times. Tsubame, where TOJIRO is located, is a metal-processing industrial cluster known as “Tsubame-Sanjo.”

Since the manufacture of Wakugi (Japanese nails) started in the early 1600s, knives, files, pipes, copperware, metal carving, cutlery, and other products have been manufactured here, increasing exports.

TOJIRO has delivered products from the representative production area of Japan to the world, where professional vendors of each process have developed techniques and spirit together through friendly competition.